There are experiences one never forgets — and our visit to HAUS Centrifuge Technologies in Ayvalık was truly one of them.

Our first day began with visits to olive mills that had installed the Oleaphenol unit. We saw the machine installed in different configurations and tested various olive oil extractions from the same variety. Although the machines were identical, the olive oils produced showed great differences - the reason being, clearly, the handling of the machine and the management of the fruit. Naturally, we helped the mill operators by pointing out mistakes we observed in their production processes so they could improve their final product.

Through these visits, we had the opportunity to discuss and deeply understand the need for proper training — both for olive millers and for the operators of the olive mill itself.

The next day, we would visit the factory in Aydın!

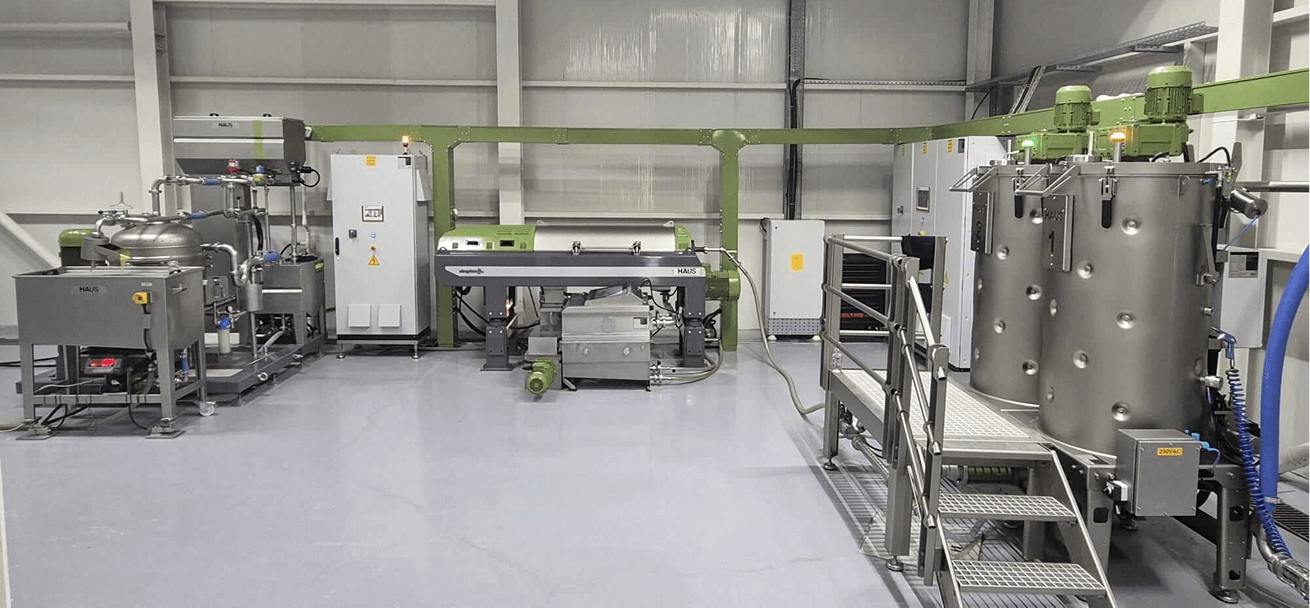

From the moment I passed through the gates of the vertically integrated facility, I knew I was about to experience something special. The environment radiated energy, creativity, and a passion for both technology and olive oil.

I had the chance to follow, step by step, the process of constructing the Oleaphenol — a machine designed to produce something precious: olive oil with high phenolic content.

Oleaphenol is the result of years of research and engineering development. It was designed to maximize the recovery of phenolic compounds from olives while fully preserving their natural bioactivity.

Its technology is based on:

The attention to detail, the precision of the assembly, and the dedication of the HAUS team were impressive. Every stage of construction reflected deep knowledge and respect for the product.

But the highlight of the visit came when they invited me to perform an olive oil extraction right there in the factory. It was a deeply emotional moment to stand beside them, watching the technology come to life before our eyes.

Together, we managed to produce three distinct olive oils, each with its own personality — different aromas, colors, and phenolic profiles. The results spoke for themselves: a high-quality extra virgin olive oil that combined technology, knowledge, and passion.

Each sample carried its own “signature”:

This process proved that modern centrifugation technology can harmoniously work with the natural complexity of the olive, creating oils that stand out not only for their flavor but also for their bioactive value.

Beyond the machines and the technology, what touched me most were the people.

Hakki, Ozden, Spyros, Yusuf, Okan, Christos, and the entire HAUS team, as well as Petros Petropoulos SA: a huge thank-you for your hospitality, warmth, and trust. You honored me with your collaboration and with the opportunity to share this experience — to learn from one another, exchange ideas, and witness true innovation in action.

Leaving HAUS, I felt deep gratitude and inspiration. Because there, among stainless steel components, centrifugal separators, and green olives, I realized something simple yet fundamental: when technology meets experience, and when people work together with a shared vision, the results can exceed all expectations.